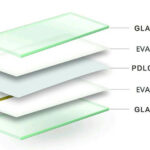

Features of eva film for glass lamination

- Low processing temperatre

- Processing at 110 ℃ , that is 20 ℃ lower than that of traditional eva film

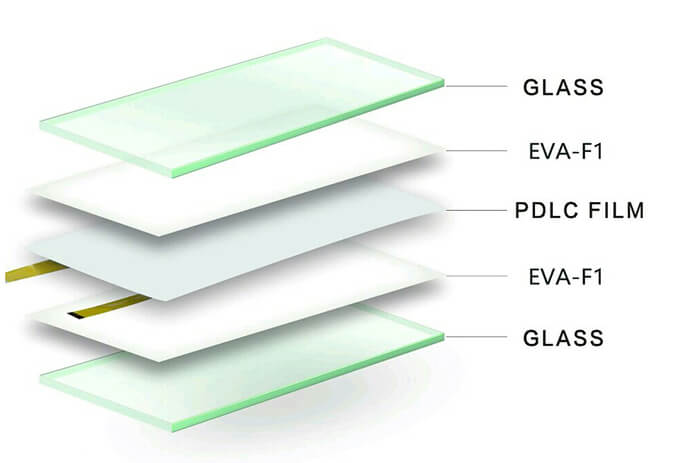

- Great compatibility with PDLC film

- Its adhesion with PDLC film is neither too strong nor too weak . If it is too strong , PDLC film will get a strong tensile force from eva film , which is of a devastaing effect. If it is too weak, de – lamination problem will appear.

- Perform high definition for smart glass

- Transparency with 92% , Haze 0.2%

Technical data

| Item | ||

| Thickness(mm) | 0.38 | 0.76 |

| width(m) | 2m – 2.5m | 2m – 2.5m |

| Length (m) | 100 | 50 |

| Tensile strength | >10 MPA | >10 MPA |

| hardness | 75HA | 75HA |

| Adhesion with glass | 100 N /CM | 100 N /CM |

| Elongation | 500% | 500% |

| Water absorption | < 0.1% | < 0.1% |

| Transmittance | 92% | 92% |

| Haze | <0.2% | <0.2% |

| UV filter | >99% | >99% |

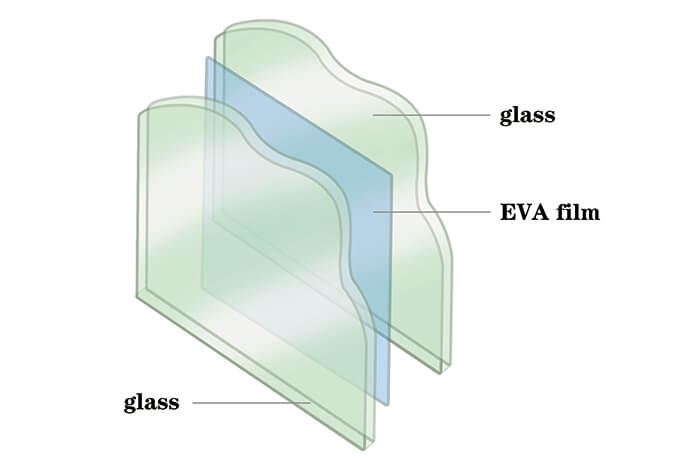

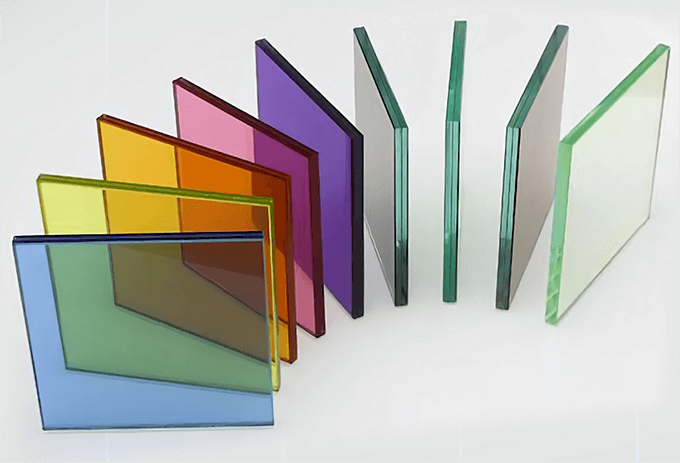

Application of eva film for glass lamination