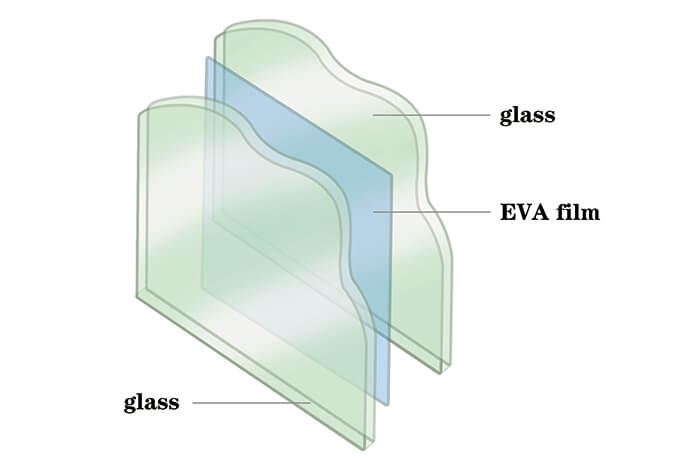

EVA film

The EVA film we are offering are thermoset material and will form into an extreme stable inner structure after lamination. All the eva film could be used both in outdoor and indoor without the risk of de- lamination , yellow turning or haze appearing with gurranty of 10 years .

It is SGCC certificated eva interlayer .