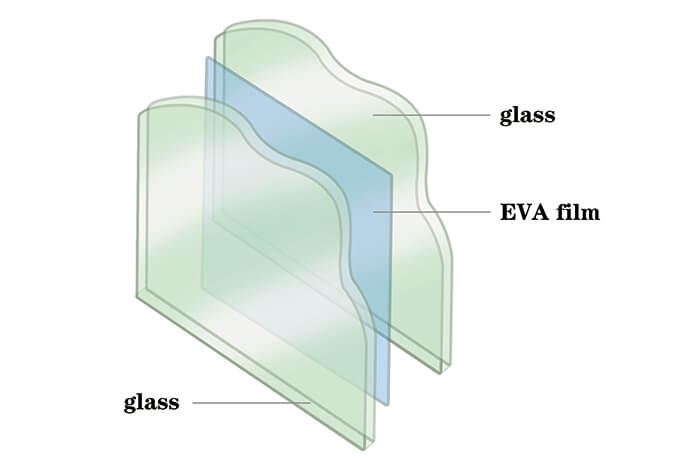

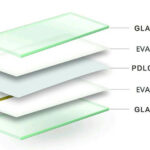

Bubble is the most common and annoying problem during eva lamination process . It will help a lot if we know how it come from and how to avoid it . There are 3 typical kinds of bubble . Today , I am going to analyze how different kind of bubble happen and how to avoid .

1. Small bubble appearing along the edge of eva laminated glass

This bubble is usually cuased by stopping vacuum pump too early. We are supposed to stop vacuum pump when the glass temperature drop to less than 60℃ . If vacuum pump is stopped too earily and glass temperature is still high , the meltd eva film between glass will take in air . That is how the bubble appear .

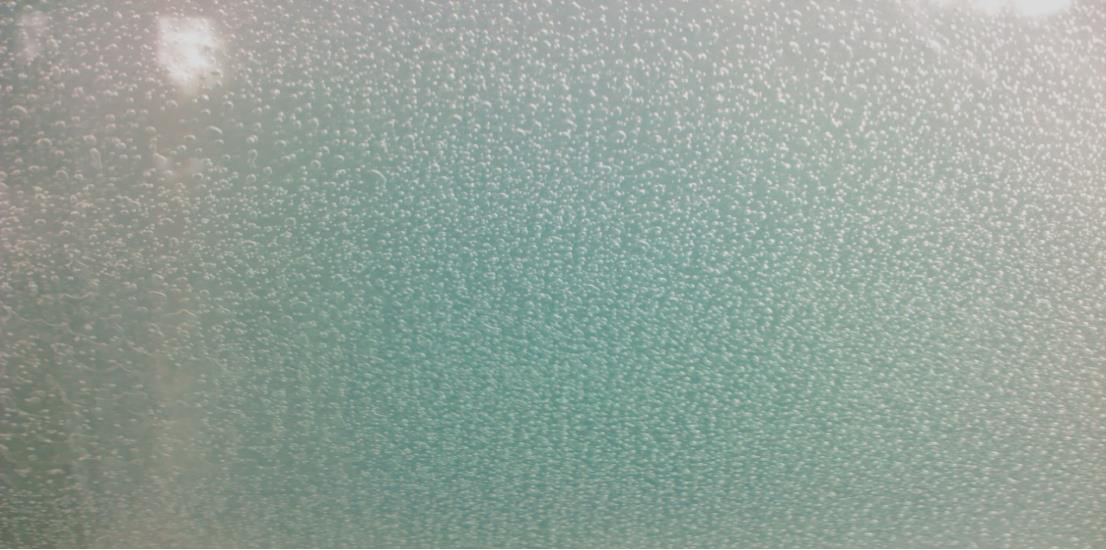

2. Bubble appear on nearly everywhere of eva laminated glass

If bubble appear at a large area on glass , there must be lots of air left inside the vacuum bag and these air form ito bubble everywhere . Why does the air left inside silicon bag ? A lot of possible reason, mkae sure vacuum pump work well , check the air tightness of vacuum bag and vacuum tube and so on . That means please make sure 100% that the environment inside vacuum bag is actually vacuum.

If bubble appear at a large area on glass , there must be lots of air left inside the vacuum bag and these air form ito bubble everywhere . Why does the air left inside silicon bag ? A lot of possible reason, mkae sure vacuum pump work well , check the air tightness of vacuum bag and vacuum tube and so on . That means please make sure 100% that the environment inside vacuum bag is actually vacuum.

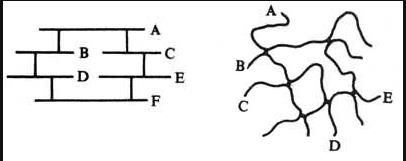

3. Bigger bubble in the shape of strip

This bubble is likly to appear during EVA film toughened glass lamination . When toughened glass in not in a good tempering condition, its surface will not as flat as plate glass . In this way , it need thicker eva film to be filled up .If not , bubble will appear . Two solutions for it . One is to use thickner eva film . Another way is to temper the glass in pair and lamiate this pair together .

This bubble is likly to appear during EVA film toughened glass lamination . When toughened glass in not in a good tempering condition, its surface will not as flat as plate glass . In this way , it need thicker eva film to be filled up .If not , bubble will appear . Two solutions for it . One is to use thickner eva film . Another way is to temper the glass in pair and lamiate this pair together .

If you have more questions on eva glass lamination process , please kindly contact us and we would be glad to discuss together !