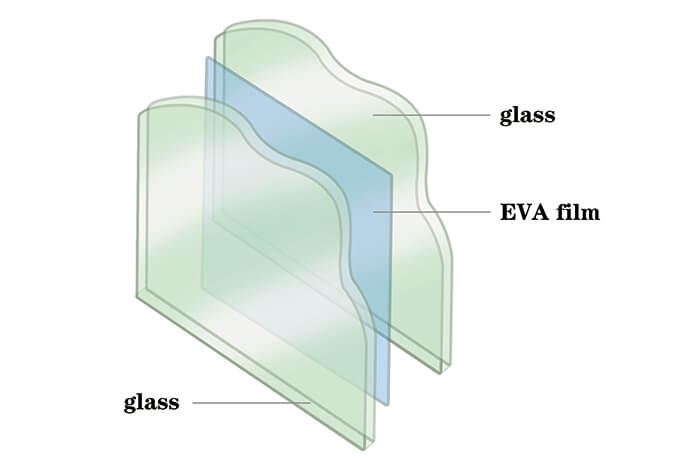

EVA is short for ethylene-vinyl acetate copolymer and PVB is short for polyvinyl butyral. EVA film and PVB film are two common interlayers used for laminated glass. However, they differ a lot from each other in performance and application .

Storage:

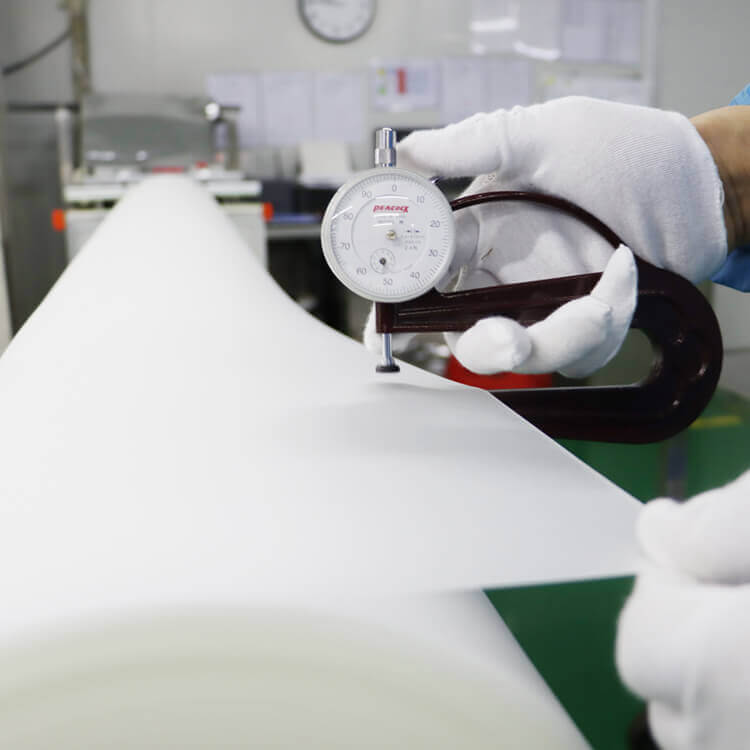

EVA film has very good moisture resistance, so its storage conditions are very loose ( temperature≤ 35 ℃ ; humidity ≤60% ); PVB film has a high water absorption rate . So ,its storage conditions are harsher(with temperature at 18℃ – 22℃ and humidity at 25% – 44%)

Lamination equipment:

The equipment needed for making eva laminated glass is furnace . The cost of one furnace is lower (12,000 to 20,000 U.S. dollars); Autoclave is needed when making PVB film laminated glass and the cost of an autoclave is about 9 times bigger than that of an EVA lamination furnace .

Stability :

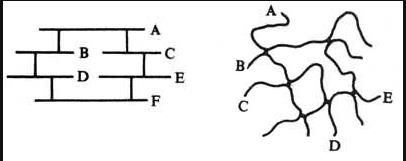

Our EVA film is a thermoset material . After lamination , EVA film will form into a three- dimensional inner structure . This structure is irreversible and will not melt when heated again . While PVB film forms a coupling structure after lamination, and the structure of PVB laminated glass will become softer or harder under extremely hot or cold temperatures, which will result in a decrease of adhesion to the glass and bring the risk of de – lamination .

Humidity resistance:

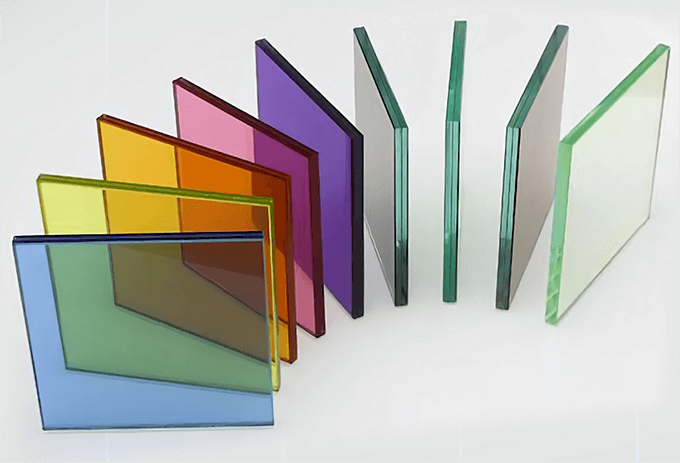

The water absorption rate of EVA film is less than 0.1%; while the water absorption rate of PVB film is 5 times higher. Therefore, EVA laminated glass has obvious advantages in some area with high humidity, such as bathrooms, seaside, swimming pools, etc. You don’t need to worry that the eva laminated glass will absorb water and get de-lamination.

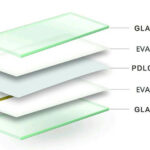

EVA film is more suitable for smart glass laminating:

The processing temperature range of EVA film could be from 110 ℃ – 130 ℃ . As we know PDLC film is an heat sensitive material and it may get shriked when being exposed to extra high temperature , so we can choose low temperature eva film to work with it when laminating smart glass . While processing temperature of PVB is 130℃ .